The computer doesn't always know whats right.

Oct 13, 2017Introduction

The vehicle we were working on is a 99 Subaru Legacy Wagon 2.2 motor and 5 speed manual trans. The code present was P1507 for the idle air control solenoid. The symptom was intermittent stalling when coming up to a stop light or intermittent hard starting. I had this DTC and wanted to know if or how I could test the IAC before I replaced it. I googled it and after much reading of people who did not have a diagnostic process to their approach and just started throwing parts at it hoping to fix it, I found that it could either be the IAC or a neutral switch causing the problem. Seeing as the IAC is about $180 or more and the switch is $20-30 I decided to do some testing to figure out which it is before I go spending too much money unnecessarily.

I decided to do a thorough write up and explain why sometimes a gear position sensor sets a code for the idle air control in this particular model year Subaru.

The correct part number for this switch is 32008AA074. It says it applies to 93-05 Subaru Legacy, Impreza or Forester (of course with the manual transmission)

Initial Testing

Before I replaced the switch, I tested the old switch using a multimeter. When the button was fully pressed in it should read O.L. and when it was not pressed it should read some number in ohms. I could not find a specification in service information or on the internet. The old switch would drop to O.L. intermittently throughout the stroke of the button and would sometimes not read O.L. when completely pushed in. The new switch would read O.L. when pushed in and a variable amount of resistance during the stroke.

Some Technical Background

The 06 and up Subaru uses a different Neutral Switch and the computer actually monitors it and has a code for it. This particular Subaru doesn’t have a code for a bad gear position sensor. It was an oversight which they fixed in the 06 and up model. This switch here just monitors the position of the gear shifter and tells the computer if it is in gear or in neutral. I assume that the computer uses this information to determine which fuel map to use and if it can’t tell if the vehicle is in neutral then it defaults to the incorrect fuel map and the engine stalls or will not start and the conditions meet the requirements to set the code for the IAC instead.

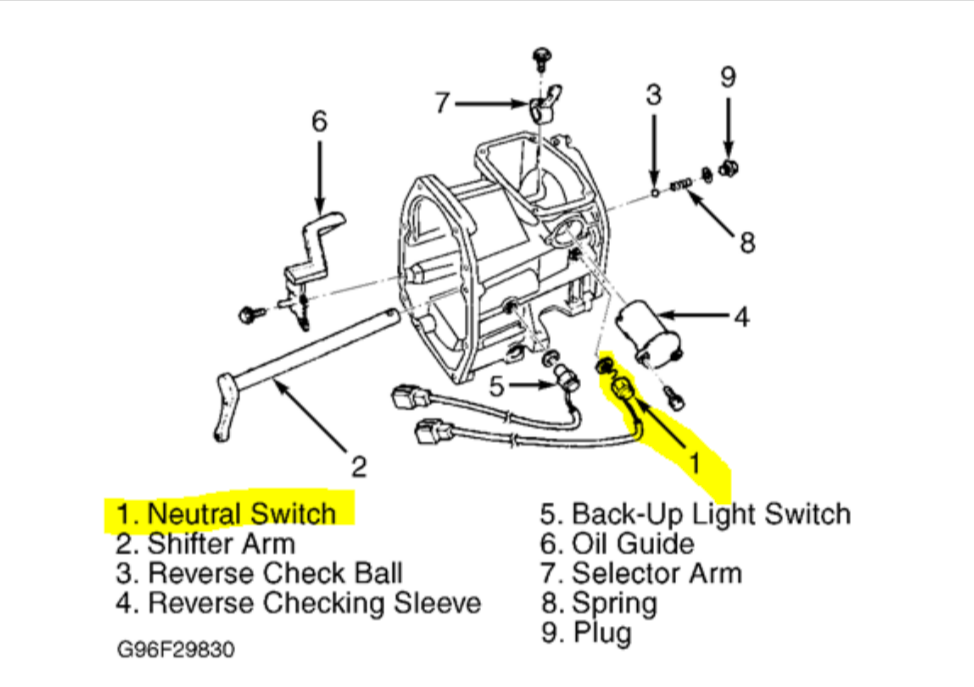

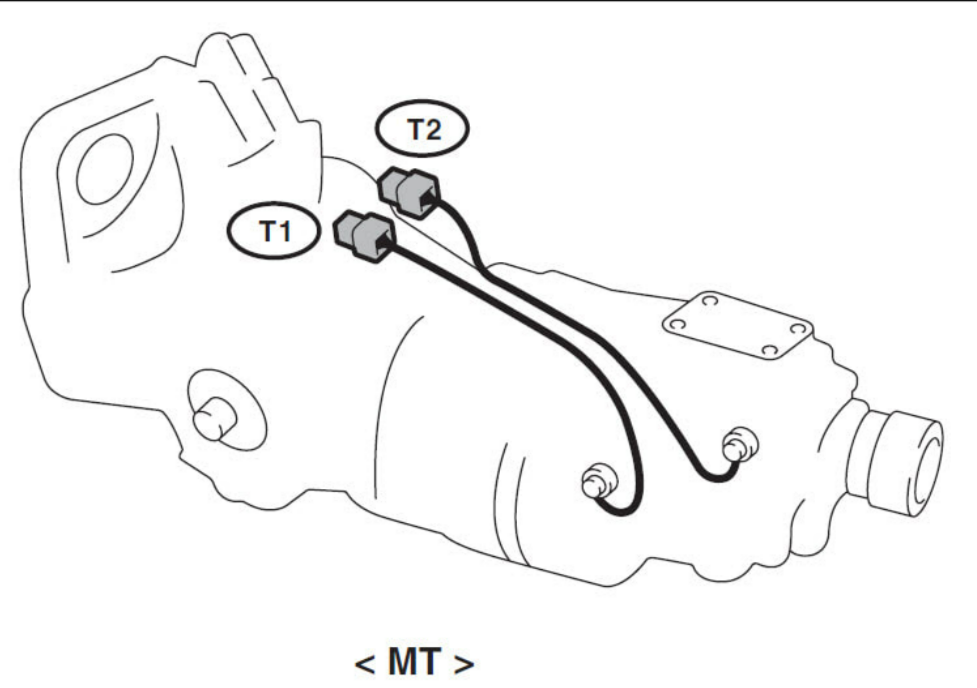

The neutral switch (terminal T2 in the picture below) has two black wires and a brown plug. The backup switch (T1) has brown with a blue stripe wires and a green plug.

Dealing with Parts Departments

If you try to call the parts department at the local dealer and tell them you need a neutral switch for this vehicle they will try to send you the neutral safety switch attached to your clutch pedal. Not the same thing and they could not understand that there was another neutral switch.

If you try to call the local parts store they will tell you the only part there is #5 the Back-Up Light Switch. Also, not the same thing. The wire harness plug is different and the wires are different color. (Internally I think they are the same but why hack and splice wires when you can get the correct part.)

The neutral switch for the 06 and up vehicles is not the same either. After much searching I was able to find a part number for the correct part. I asked the dealer and they still couldn’t find it. I asked the local parts stores about this number and they said that number cross referenced to the backup light switch. Still no progress. So, I went to amazon and typed in the number and found it there in a factory Subaru package with the correct part number on it. I replaced the switch and have not had any problems with that switch since.

In summary:

The computer cannot always tell you what is wrong with your vehicle. You need to have a diagnostic approach to solving problems. Testing parts before you replace them can save you time and money. I checked and verified that this switch was bad before I replaced it using the seven-step process:

- Verify the complaint

- Visual inspection

- Gather data

- Develop plan

- Perform tests

- Determine root cause and complete repair

- Verify repair